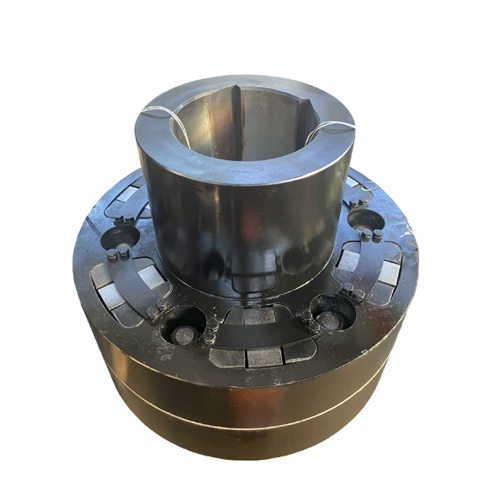

Products Description

LKElastic Block CouplingIt Is A Transmission Component With Elastic Blocks As The Core, Consisting Of Two Half Couplings With Convex Teeth And An Intermediate Elastic Block. Half Couplings Are Often Forged From 45 Steel Or Cast Iron, With Convex Teeth Evenly Distributed Along The Circumference; The Elastic Block Is Made Of Polyurethane Or Nitrile Rubber Material, And Is Tightly Fitted With The Protruding Teeth Through Compression Molding.

During Operation, The Convex Teeth Of The Active Half Coupling Compress The Elastic Block, Transmitting Torque Through The Elastic Deformation Of The Elastic Block. At The Same Time, It Can Compensate For Radial (≤ 0.4mm), Angular (≤ 2 °), And A Small Amount Of Axial (≤ 1.2mm) Offset, And Can Absorb Some Vibration And Impact. Its Transmission Torque Range Is 30~10000N · M, And The Allowable Speed Varies From 3500~900r/min Depending On The Model. It Is Suitable For Small And Medium Power Transmission Systems Such As Mixers, Conveying Equipment, And Textile Machinery.

The Advantage Of This Coupling Is That It Is Easy To Install, And The Replacement Of The Elastic Block Does Not Require Moving The Shaft System; Rubber Material Elastic Blocks Have Good Shock Absorption Effect, While Polyurethane Material Is More Wear-resistant And Oil Resistant. However, The Temperature Resistance Range Of The Elastic Block Is Limited (-25 ℃~85 ℃), And It Is Prone To Aging In Long-term High Temperature Or Oily Environments. Regular Inspection Of The Wear And Cracks Of The Elastic Block During Maintenance Is Necessary To Avoid Overload Use, Which Is A Practical Transmission Choice That Balances Buffering And Economy.