Products Description

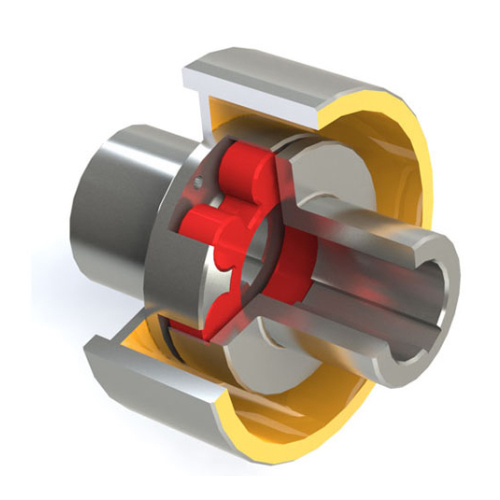

MLL Brake Wheel Type Plum Blossom Elastic CouplingIt Is A High-performance Transmission Component With Integrated Braking Function, Designed To Integrate The Elastic Compensation Characteristics Of The Plum Blossom Coupling With The Safety Control Capability Of The Braking Wheel, Suitable For Industrial Scenarios With High Requirements For Transmission Reliability And Braking Response. This Coupling Complies With The GB/T 5272-2002 Standard And Is Divided Into Two Structural Forms: MLL-I Type (split Brake Wheel) And MLL-II Type (integral Brake Wheel). The Core Consists Of A Half Coupling With Protruding Claws, A Plum Blossom Shaped Elastic Body, And A Brake Wheel.

The MLL-I Type Adopts A Split Type Brake Wheel Structure, And The Brake Wheel Is Connected To The Half Coupling Through Bolts. When Replacing The Elastic Body, There Is No Need To Disassemble The Entire Coupling, Which Significantly Improves Maintenance Convenience. The MLL-II Model Integrates The Brake Wheel And Half Coupling Design, With A More Compact Radial Size, Suitable For Installation Environments With Limited Space.

The Power Is Transmitted Through The Engagement Between The Plum Blossom Shaped Elastic Body And The Half Coupling Claw. The Drum Shaped Flap Design Of The Elastic Body Optimizes The Force Distribution, Compensates For Axial (≤ 5mm), Radial (≤ 0.5mm), And Angular (≤ 1.5 °) Deviations, And Absorbs Vibration Impacts. The Brake Wheels Are Made Of 45 Forged Steel (D ≤ 200mm) Or ZG340-570 Cast Steel (D ≥ 250mm), And Emergency Braking Is Achieved Through Friction Plates Or Hydraulic Devices. The Braking Torque Range Covers 250~12500N · M, And The Response Time Is As Short As Milliseconds.

Nominal Torque: MLL-I Type 25~12500N · M, MLL-II Type 250~12500N · M

Allowable Speed: MLL-I Type 1500-15300r/min, MLL-II Type 4750-950r/min

Temperature Range: -35 ℃~+80 ℃

Elastic Material: High-strength Polyurethane (wear-resistant And Oil Resistant) Or Nitrile Rubber (high Elasticity)